![]()

![]()

![]()

Trusted supplier of ISO 9001-certified excavator bucket parts: teeth, adapters & wear plates with over 10 years expertise. Offering custom designs, bulk orders and fast global delivery. Engineered for maximum durability in mining and construction applications.

At NINGBO HUIFENG MACHINERY SPARE PARTS CO.,LTD, we engineer high-performance excavator bucket parts—teeth, adapters, and wear plates—to combat wear, reduce downtime, and maximize cost-efficiency for global mining, construction, and demolition operations.

Standard (STD): For general digging tasks

Rock Chisel (RC): Designed for hard rock excavation

Twin Tiger (WTL): Ideal for frozen ground

Tiger Long (TL): Optimized for low-abrasion coal environments

Universal (SYL): Versatile for mixed soil and rocky conditions

High-impact steel (T-0 to T-3 grades) with AKV ≥20J/cm²

Casting, Forging and Pre-coated sand

Caterpillar, Komatsu, Volvo and more (1–200-ton machines)

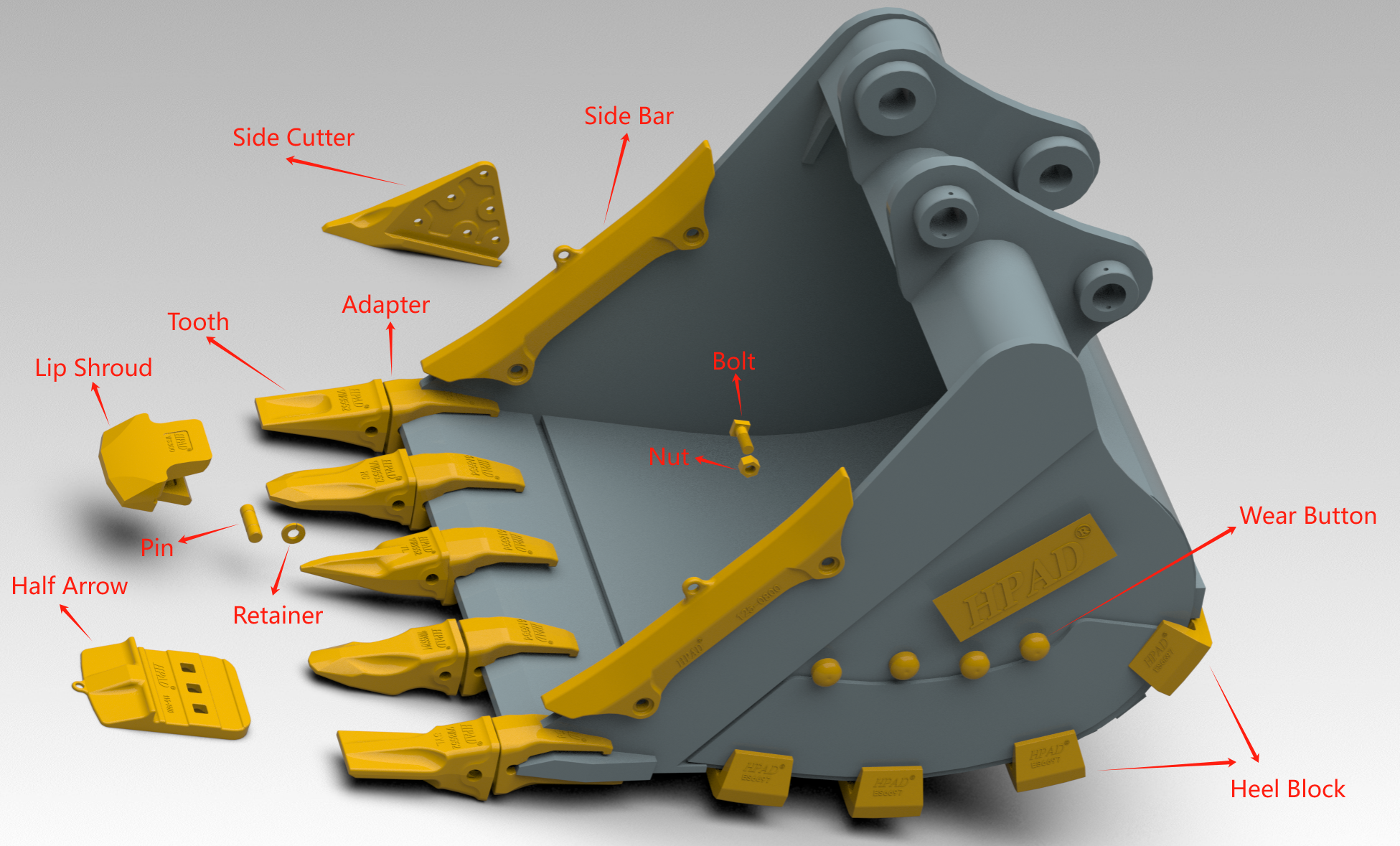

Types: Side cutters, heel blocks, lip shrouds, half-arrows, side bar protectors.

Installation: Bolt-on (50% faster replacement) or weld-on

Hardness: 400–500 Brinell for extreme abrasion resistance

Options: Weld-on (max strength) or bolt-on (quick-change)

Durability: Heat-treated alloy steel withstands 20+ ton loads

Fit: 10,000+ machine specifications covered

| Challenges | Our Solutions |

| Premature part failure | 30% longer lifespan via forged alloys & precision manufacturing |

| Incompatibility issues | 10,000+ machine-fit database + custom engineering |

| Costly OEM replacements | OEM-grade excavator bucket parts at 30–50% lower cost + 12-month warranty |

| Installation complexity | Modular, tool-free designs for rapid replacement |

✅ ISO 9001-Certified Quality: 100% non-destructive testing + pre-shipment inspections

✅ Fast Logistics & Technical Support: Dedicated engineers, 24/7 technical assistance, CAD drawings

✅ Cost Optimization: Bulk pricing, 20–40% reduced lifecycle costs, free samples

Challenge: European bucket parts failed within 200 hours

Solution: Heavy-duty custom design

Result: 500+ hours with retained edge sharpness

Challenge: Premature pocket wear

Solution: Reinforced pocket design

Result: 50% longer wear life

Challenge: Loose-fit teeth from competitors

Solution: Precision-tolerance XS40RC teeth

Result: Secure, perfect fit

Custom specifications

30% faster lead times

Global shipping

12-month warranty

Email: info@tigerget.com

WhatsApp/Telegram: 0086-13957476951

Website: http://www.hpad-get.com/

Contact: WANGWEI

Phone: 0086-13957476951

E-mail: info@tigerget.com

Add: Room No.401-36,TianJian Lane No.26,Yinzhou District,Ningbo City.