Request durable excavator bucket heel shrouds? We’re a leading manufacturer offering custom, HARDOX/AR steel shrouds (fits CAT/Komatsu). 360-500 BHN with ISO-certified. Free quote—request now!

Stop Losing Money to Worn-Out Excavator Bucket Heel Shrouds

Is your excavator sidelined because its excavator bucket heel shroud wore seriously? For construction fleet managers and mining procurement teams, this isn’t a minor repair. Industry data shows replacing a failed heel shroud costs $2,000–$5,000 in parts + 8–12 hours of downtime (that’s $8,000–$15,000 in lost productivity for mid-sized excavators).

The excavator bucket heel shroud is the unsung hero of your digging equipment: It is welded to the bucket’s rear edge to take the full brunt of abrasion when dragging through rock, gravel, or concrete. If the quality is very poor, you’ll face frequent replacements, accelerated bucket damage (a $10,000+ repair!), and missed project deadlines.

This guide shows you how to source high-performance excavator bucket heel shrouds, and why global buyers trust us.

## What Are Excavator Bucket Heel Shrouds? Why They Can’t Be Skimped On

### Definition: The "Shield" of Your Excavator Bucket

Excavator bucket heel shrouds (also called side shrouds or side cutters) are made of thick and reforced steel plates. It can be weld on the heel of excavator buckets. Unlike standard bucket edges, they’re designed to absorb extreme friction and impact to protect the bucket’s original structure from premature wear.

### Why Cheap Heel Shrouds Cost More

Low-quality shrouds fail fast, leading to a chain reaction:

1. Rapid thinning: Wears down in the short time, exposing the bucket to damage.

2. Cracking & breaking: Weak material cracks under heavy load and there is a risk of debris flying during operation.

3. Hidden costs: Frequent replacements and bucket repairs add up to more than $20,000 annually per excavator.

The Solution? Invest in OEM-grade excavator bucket heel shrouds. Although the initial cost is 15% higher, it can reduce the total ownership cost by 40%.

## How We Make Excavator Bucket Heel Shrouds That Outlast the Competition

Not all heel shrouds are created equal. Our manufacturing process is engineered for durability, perfect fit and performance. Here are our advantages:

### 1. Premium Abrasion-Resistant (AR) Steel: The Foundation of Longevity

We only use top-grade AR steel and wear-resistant alloys—no standard carbon steel. Our material options include:

- **NM450/NM500**: Perfect for heavy mining and concrete demolition (tensile strength ≥ 1,200 MPa).

- **JIS SM490 + Hardfacing**: Custom option for extreme wear (adds 3mm wear layer, extending life by 50%).

*Why this matters*: A HARDOX 450 shroud lasts 3x longer than a standard carbon steel steel shroud in the same working conditions.

A shroud that doesn’t fit perfectly will lead to gaps, wobbles, and wears unevenly. We solve this with:

- **Hydraulic forming**: Shapes the shroud to your bucket’s curve (no forced welding, which weakens the material).

- **Pre-weld prep**: Beveled edges for strong, seamless welding (reduces cracking at the joint).

*Our guarantee*: Our excavator bucket heel shrouds fit 98% of mainstream models (CAT 320/336, Komatsu PC200/PC360, Volvo EC220, Hitachi ZX210) without modifications.

### 2. Controlled Hardness: Balance of Wear Resistance and Toughness

Too hard = brittle; too soft = wears fast. We carry out meticulous to achieve the best performance:

- **Hardness range**: 360–500 BHN (adjustable based on your use case).

- **Tempering process**: Double-tempered to reduce internal stress (prevents cracking under impact).

### 3. Customization for Your Exact Needs

We don’t force you to fit "one-size-fits-all" shrouds. We offer full customization:

- **Size**: Any length (200mm–1,500mm) and thickness (10mm–30mm).

- **Design**: Cutouts, holes, or notches per your drawings (send CAD files or samples).

- **Branding**: Engrave your logo or part number (free for orders over 50 pieces).

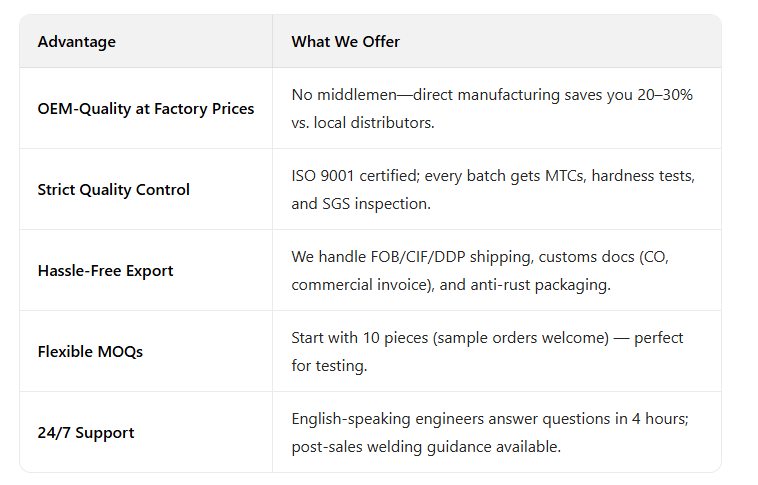

## Why Global Buyers Choose Our Excavator Bucket Heel Shrouds?

We’ve supplied 5,000+ clients in 60+ countries (US, Australia, Germany, Brazil) for 12 years, here are our advantages:

## FAQ:

### Q1: Will your shrouds fit my [CAT/Komatsu/Volvo] excavator?

A: Yes. We have a database of 2,000+ bucket models. Tell us your part number or bucket dimensions, and we’ll match the exact shroud.

### Q2: What’s the lead time for custom excavator bucket heel shrouds?

A: Standard models: 40 days. Custom designs: 50-60 days. Rush orders available for emergency needs.

### Q3: Do you provide samples? How much do they cost?

A: Free samples (up to 2 pieces) for qualified buyers. You only pay shipping, we’ll send samples within 3 days of your request.

### Q4: What’s your warranty on heel shrouds?

A: 12-month warranty against material defects. If a shroud cracks or wears abnormally within 6 months, we’ll replace it for free.

### Q5: How do I choose the right steel?

A: Our engineers will help! Share your working conditions (e.g., "digging granite" or "handling sand") and we’ll recommend the best material .

## Take Action: Get Free Quote Today

Don’t let worn-out excavator bucket heel shrouds slow down your projects. Test our quality risk-free:

✅ **Free sample kit**: 2 shroud samples (your choice of material) and compatibility guide.

✅ **Custom drawings**: Send us your bucket specs, and we’ll provide 2D/3D drawings in 24 hours.

✅ **10% off first order**: For new clients who confirm within 7 days of quoting.

**Click Here to Request Your Excavator Bucket Heel Shroud Sample & Quote**

Call our export team: +86-13957476951 | Email: info@tigerget.com | WhatsApp: +86-13957476951

Contact: WANGWEI

Phone: 0086-13957476951

E-mail: info@tigerget.com

Add: Room No.401-36,TianJian Lane No.26,Yinzhou District,Ningbo City.