For heavy equipment procurement managers, mining operations directors, and construction fleet supervisors, excavator bucket wear means a maintenance issue, it’s a hidden cost. Although the bucket teeth are damaged by the impact, the sides of your bucket bear constant abrasive stress from rocks, gravel, and soil. Premature thinning, cracking, or warping of side-plate forces costly repairs or full bucket replacements and stalls projects for days.

High-quality excavator bucket side cutters. These components don’t only protect your bucket, they also boost efficiency, reduce fuel costs, and extend your equipment’s life. This guide will show you how to choose the right side cutters, How to select supplier?

## 1. 3 Core Benefits of Premium Excavator Bucket Side Cutters

Installing the right side cutters isn’t an expense, it’s an investment. Here are the reasons:

### a. Slash Bucket Wear and Replacement Costs

Excavator bucket side cutters act as a sacrificial barrier between your bucket’s side plates and abrasive materials. Instead of the bucket itself wearing thin, the side cutter takes the brunt of the damage.

### b. Boost Digging Efficiency and Reduce Fuel Use

Sharp, well-fitted side cutters slice through soil, rock, and debris with less resistance, reducing drag on the bucket. This means:

- Faster cycle times (10–15% more loads per shift).

- Lower fuel consumption (up to 8% less per hour, according to construction equipment studies).

- Less strain on your excavator’s hydraulic system (extending pump and cylinder life).

### c. Maintain Full Bucket Capacity

Worn side plates shrink your bucket’s effective volume over time, so you move less material per pass. Side cutters can prevent inward wear, and keep the bucket’s original geometry intact.

- Example: A 20-ton excavator with worn side plates might lose 5–10% of its capacity. With side cutters, you maintain full load volume for every dig.

## 2. How to Choose the Best Excavator Bucket Side Cutter (5 Critical Criteria)

Not all side cutters are created equal. Cheap, generic options will wear out in weeks and can accelerate bucket damage. Use these criteria to select high quality side cutter:

### a. Material & Hardness: The Foundation of Durability

The most important factor determining a side cutter’s lifespan is its steel quality and hardness.

- **Premium Steels**: Look for high-carbon boron steel, NM450/NM500 wear-resistant steel, or alloy steels. These balance:

- *Hardness*: 450–500 HB (Brinell Hardness) to resist abrasion.

- *Toughness*: To avoid chipping or cracking on impact (critical for rocky terrain).

- **Red Flag**: Suppliers who only mention “high hardness” without mentioning toughness, brittle steel will break under heavy use.

### b. OEM Compatibility & Precision Fit

A side cutter that almost fits is worse than no cutter at all. Poor fit creates gaps where material gets trapped, causing corrosion and uneven wear on the bucket.

- **100% OEM Matching**: Choose cutters engineered for your specific excavator brand/model (Caterpillar, Komatsu, Hitachi, Volvo, etc.).

- **Quality Check**: Request 3D scanning reports or dimensional tolerance data.

- *Pro Tip*: Avoid universal side cutters—they rarely fit perfectly and often lead to more problems.

### c. Design & Profile: Match to Your Application

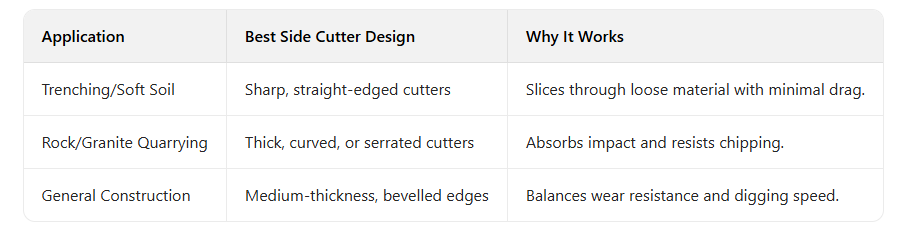

Side cutters come in different designs for different applications. Select one tailored to your work:

### d. Heat Treatment: For Consistent Performance

Even the best steel have to work with the proper heat treatment. Top suppliers use computer-controlled quenching and tempering to:

- Ensure uniform hardness across the entire cutter.

- Prevent brittleness (a common issue with cheap, over-hardened cutters).

- Ask: “Can you provide heat treatment records for each batch?”

### e. Weld-ability (For Permanent Installation)

If you prefer welded side cutters (instead of bolt-on), check the steel is weld-friendly or not. Low-quality steels may crack during welding, leading to premature failure.

## 3. What to Look for in an Excavator Bucket Side Cutter Supplier (B2B Buyer’s Checklist)

The reliability of the supplier is as important as the products. For international B2B buyers, these factors are non-negotiable:

### a. Application Expertise (Not Just Selling Parts)

A great supplier doesn’t only list products—but also they help you choose the right cutter for your application. Ask:

- “What side cutter material/profiles work best for [your application, e.g., sandstone mining]?”

- “Can you share case studies of clients in my industry?”

- Red Flag: Suppliers who can’t answer industry-specific questions.

### b. Customization Capabilities

If you have a specialized bucket (e.g., narrow trench buckets, heavy-duty mining buckets), look for suppliers who offer custom side cutters. This includes:

- Custom sizes, thicknesses, or profiles.

- Fast delivery (2–3 weeks for custom orders).

### c. Quality Certifications & Traceability

Trust is built on proof. Demand:

- **ISO 9001 Certification**: Ensures a structured quality management system.

- **Batch Traceability**: The ability to track a cutter back to its raw material and productive process.

### d. Global Export Experience

For international buyers, logistics can make or break a deal. Choose a supplier with:

- **Export Expertise**: Experience shipping to your region (e.g., EU, North America, Australia) and handling docs like Bill of Lading, Certificate of Origin.

- **Protective Packaging**: Plastic packing bags + wooden crates to prevent damage during ocean freight.

- **On-Time Delivery**: Clear lead times (e.g., “30 days for standard orders, 40-50 days for custom”) and 24/7 shipment tracking.

### e. After-Sale Service

What if a cutter fails prematurely? Pay attention to below points:

- A warranty (12–24 months is standard for premium cutters).

- Responsive support (WhatsApp/email replies within 4 hours).

- Fast replacements for defective parts.

## Why NINGBO HUIFENG MACHINERY SPARE PARTS CO., LTD Is the First Choice for Excavator Bucket Side Cutters

For 10+ years, NINGBO HUIFENG MACHINERY SPARE PARTS CO., LTD has been a trusted partner for B2B buyers in mining, construction, and quarrying across 50+ countries. We don’t only sell side cutters, but also we deliver solutions to reduce your costs and boost productivity.

### ✅ Unbeatable Durability

Our excavator bucket side cutters are made from NM500 wear-resistant steel and 40CrMnMo alloy, hardened to 480–500 HB. The service life of the side cutter is 50% longer in abrasive conditions with computer-controlled heat treatment.

### ✅ Perfect OEM Fit

We offer 200+ side cutter models for Caterpillar, Komatsu, Hitachi, and all major brands. Each cutter is 3D-scanned to match OEM specs—no modifications needed.

### ✅ Custom Solutions for Unique Application

Our in-house engineering team designs custom side cutters for specialized buckets (e.g., 12-inch narrow trench buckets, 50-ton mining buckets) with a 14-day delivery.

### ✅ Global Shipping

We handle every step: plastic packaging, export docs, and partnerships with DHL/MAERSK for on-time delivery. Our clients in Germany, Australia, and Brazil report zero customs delays and perfect condition on every order.

### ✅ Risk-Free Guarantee

We back our side cutters with a 12-month warranty. If a cutter fails prematurely, we replace it free of charge.

## Ready to Protect Your Bucket & Boost Profits?

Stop wasting money on frequent bucket repairs. Upgrade to premium excavator bucket side cutters and start seeing ROI in months.

✅ **Click Here for a FREE Custom Quote (24-Hour Turnaround)**

(Select your excavator model, application, and quantity—we’ll send a detailed quote + spec sheet.)

**Download Our Excavator Bucket Side Cutter Catalog**

(Includes OEM compatibility charts, material specs, and case studies—free for B2B buyers.)

**Speak to Our Experts Now**

Call +86-13957476951 or email info@tigerget.com . We’ll help you pick the perfect side cutter for your job.

Your bucket is your most valuable excavator tool. Protect it with side cutters that work as hard as you do.

Contact: WANGWEI

Phone: 0086-13957476951

E-mail: info@tigerget.com

Add: Room No.401-36,TianJian Lane No.26,Yinzhou District,Ningbo City.